DURABAL BS T-Form corner profile for balconies and terraces

COLOURS:

RAL 7035

RAL 7035  RAL 1019

RAL 1019

RAL 8003

RAL 8003  RAL 8019

RAL 8019

APPLICATION AND FUNCTION:

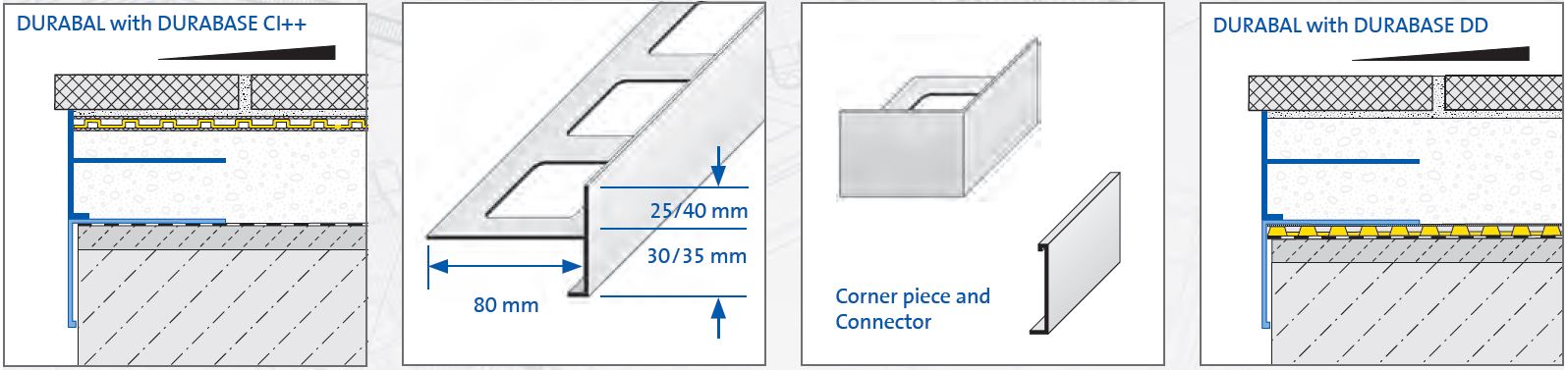

DURABAL BS balcony corner profiles with a T-shaped form are designed for use at the open edges of balcony or terrace flooring installations on conventional mortar beds. Such profiles make for a clean looking edge and protect open screed edges from weather and disintegration. Balcony construction will be covered down by L-shaped DURABAL-BW-profile.

DURABAL BS balcony corner profiles with the T-shaped form is fully embedded into the screed with its perforated square securing leg flush at the correct height then pulled away from the upper edge of the profile to the correct height. DURABASE DD should be laid between the bitumen seal of the balcony/terrace and the cement screed as drainage for the surface. This means that no water can collect within the screed or underneath it.

The profiles are linked with conneting pieces and at the corners with special corner pieces. Thus joints of about 2 mm are covered.

If DURABASE CI++ mats are installed, the screed should be scraped away to 5 mm beneath the top edge of the profile. DURABASE CI++ decouples the tiling floor from the screed foundation thus neutralising physical and thermal tensions arising at installation time in the danger area between the screed surface and the tile. DURABASE CI++ also forms a sealing system in conjunction with the tiling, which conforms to building regulations for moderately or heavily stressed flooring surfaces.

PROPERTIES AND USAGE:

No water may be allowed to collect in the screed layer in which DURABAL BS T-form balcony corner profiles are installed (surface drainage needs to be fitted). Highly alkaline aqueous solutions can attack aluminium. Application of T-form balcony profiles for special requirements of chemical and mechanical resistance should be reviewed.

MATERIAL:

DURABAL BS T-form balcony corner profiles are made of powder-coated aluminium and are available in four colours (RAL 7035, 1019, 8003, 8019).The powder coating of the aluminium profiles is colour-fast and resistant to UV and weathering. The visible surfaces should be protected from abrasion and mortar residues. Connecting and corner pieces are also available to complete the range.

For all products and materials, the following applies: The suitability of the material with regard to the expected mechanical loading and chemical exposure must be investigated carefully in each individual case. General rules of good engineering practice must always be observed!

CARE AND MAINTENANCE:

Regular cleaning not only provides for attractive appearance of aluminium or stainless steel profiles, it also reduces deposits (corrosion). All cleaning agents should be free of hydrochloric

acid (e.g. cement remover) and hydrofluoric acid. Aluminium balcony corner profiles should be cleaned when necessary using pH-neutral cleaning agents (pH 6-8) with no abrasive additives.

The manufacturers‘ product recommendations for the cleaning agents should be followed at all costs.

PRODUCT DATA:

Material: Aluminium powder coated

Colour: RAL 1019 = grey beige, RAL 8019 = grey brown, RAL 8003 = clay brown, RAL 7035 = light grey (powder coated)

Profile length: 250 cm

Height: Facing height: 55 mm, Flooring height 25 mm

Facing height: 75 mm, Flooring height 40 mm

Width of horizontal web: 80 mm

Type of use: Balcony and terrace edge profile

Manufacture: In accordance with DIN EN 755-1, “Aluminium and aluminium alloys – Extruded rod/bar, tube and profiles - Part 1: Technicalconditions for inspection and delivery”.

Coefficient of thermal expansion: Aluminium = 24 x 10-6 m/m °C