Duraflex Range Test Certificate PDF

Duraflex Expansion Profile Range PDF

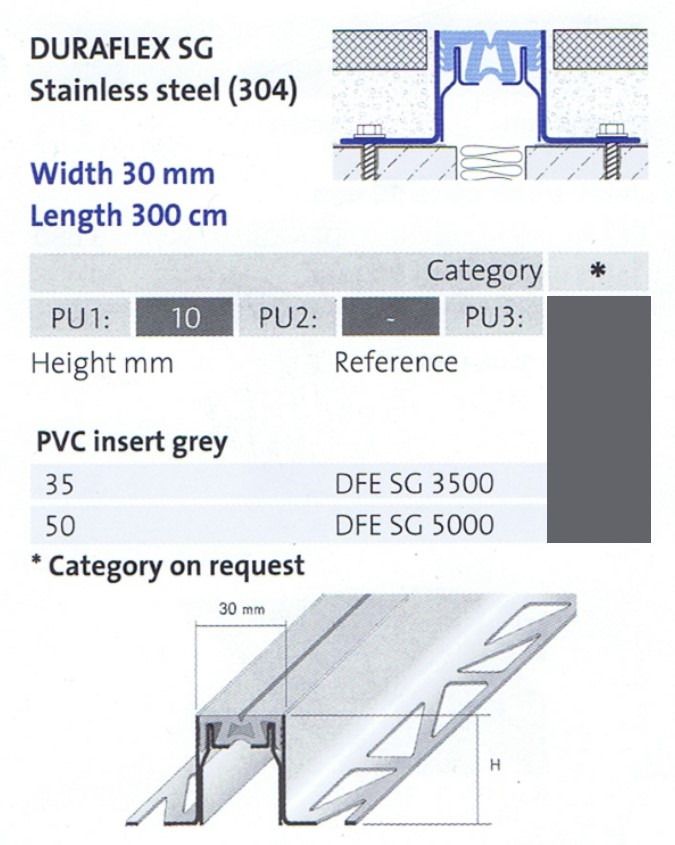

DURFLEX SG Stainless Steel

INSTALLATION:

Dural’s flexible DURAFLEX stainless steel expansion-joint profiles have been specially developed for use in highly demanding locations where resistance against corrosive substances is required. They are resistant to great stresses and can be used in retail outlets, warehouses or factories, hospitals etc. The visible surface of the profiles is either 34 mm. Loads acting at a point are evenly distributed through the covering and the bedding via the overlay.

The steel profiles at the sides are bonded with a special elastic inlay that absorbs impacts and the sound of footfall. Flexible DURAFLEX expansion joint profiles consist of a stainless steel girder section with a nitril rubber inlay that can be easily replaced. The materials are resistant to corrosive substances.

DURAFLEX expansion-joint profiles are suitable for all floor coverings (screed, natural stone, concrete etc.) and can be used anywhere. The profile must be completely embedded in the contact layer.

The use of these materials should nevertheless be carefully scrutinised with respect to their mechanical and chemical resistance in each individual instance. The inlay is anti-bacterial and physiologically harmless.

The following should be considered when choosing profiles:

DURAFLEX expansion-joint profiles do not require any special maintenance. They are resistant to fungus and bacteria. Cleaning occurs “automatically" when the tiles are cleaned. Cleaning materials may not contain hydrochloric or hydrofluoric acid and may not cause abrasion.