Particularly safe, extremely fast, noticeable cost saving - 3 mm thickness

CI++ Load Capacity - 5,000kg/m (= 5 tonnes or 50kN/m2).

-

Construction optimized 3-layer structure

-

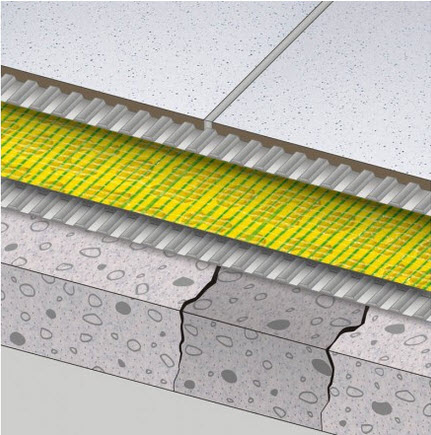

Stress alleviating and crack-bridging

-

Improves footfall sound insulation

-

Saves time and money

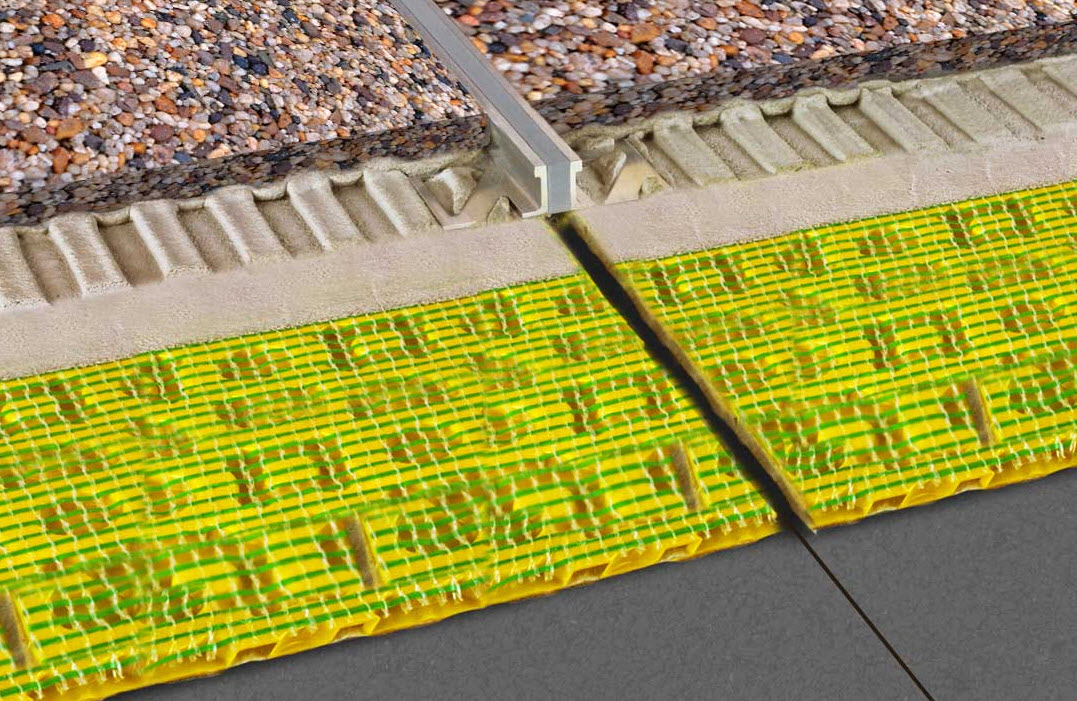

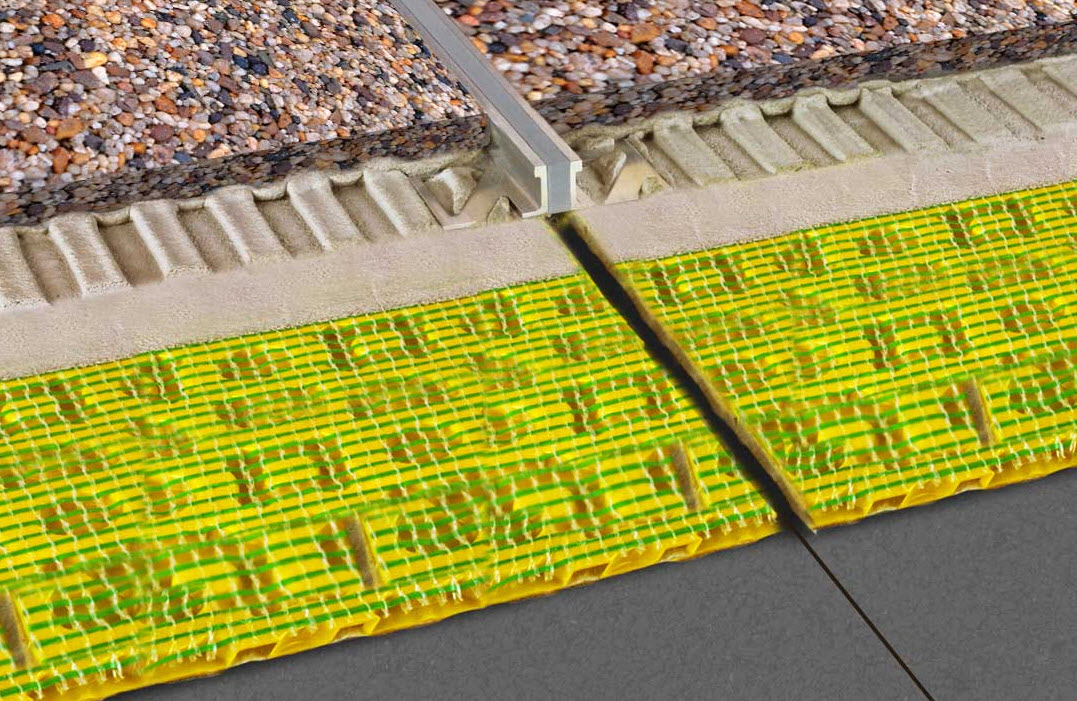

Waterproofing/Decoupling - Safe protection from below

More advantages:

-

Higher bending strength of the flooring construction

-

No roll-off effect

-

Easy to handle

-

Optimal adhesive bonding between the mat and the subfloor

-

Minimization of shear stress through active fibre fleece fabric

-

Matching accessories

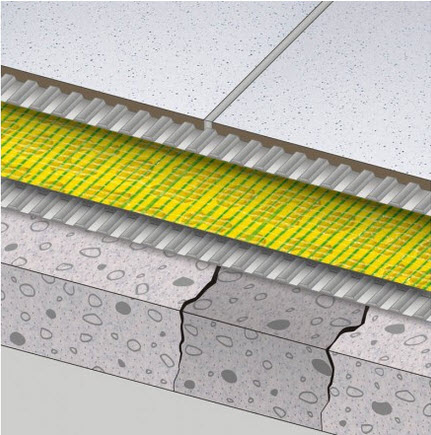

Dural decoupling mat DURABASE CI ++

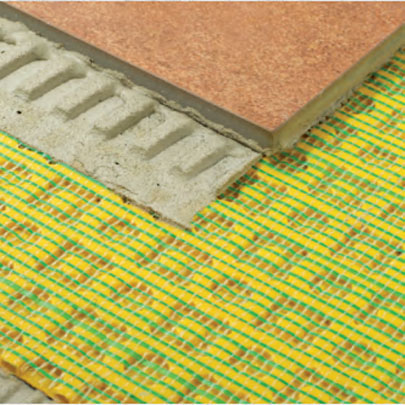

Construction optimised 3-layer structure

Mesh fabric

-

Higher bending strength of the flooring construction – stable flooring.

-

Better adhesive bonding between the mat and the thin-bed mortar.

-

No roll-off effect – the tile adhesive does not roll off when it is spread across the dimpled structure.

-

Highly resistant to mechanical loading.

Geometry of the dimples

-

The optimised shape of the dimples results in a significant reduction in the amount of adhesive required.

-

Improved equalization of water vapour pressure.

-

Optimised adhesion.

Fleece fabric with active fibres

-

The active-fibre fleece increases the adhesion surface area and guarantees optimal adhesive bonding between the mat and the subsurface.

-

The reinforced material of the fleece fabric minimises shear stresses.

Advantages for tile fitters and floor layers

-

Bridges cracks and alleviates stress

-

Functions as waterproofing in indoor applications

-

Highly resistant to mechanical loading

-

Faster laying, thanks to easier spreading of the adhesive

-

Less adhesive is required, thanks to the optimized shape of the dimples

-

Easy to handle and unroll – CI++ moulds itself to the floor (is not stiff)

-

Improved transfer of loads, in line with DIN 1055-3

-

Improves footfall sound insulation

Applications

Freshly-laid mineral subfloors

-

Cement screed

-

Calcium sulphate screed

-

Concrete

Subfloors subject to plastic deformation

-

Old synthetic flooring

-

Mastic asphalt screed

System floors

-

Double floors

-

Raised floors

Outdoor flooring

-

Balconies

-

Patios

-

Verandas

Problematic subfloors

-

Cracked subfloors

-

Mixed-material subfloors

-

Wooden subfloors

-

Heating screed

-

Dry screed

-

Metal subfloors

Large-format tiles

-

e.g. > 50 x 50 cm sufficiently thick and fracture resistant. No thin tiles – as these could break)

Advantages for architects, design engineers and developers

Time is money: CI++ allows tiles to be laid as soon as the subfloor can be walked on

In real-time, this means:

-

A time saving of around 3 to 4 weeks for cement screeds and calcium sulphate screeds – tiles can be laid after just 3 or 4 days

-

A time saving of around 3 to 4 months for concrete, depending on the quality – tiles can be laid after just 2 months or so (as opposed to 6 months)